A beam homogenizer or optical diffuser is an optical component that modifies a non-uniform input beam into a well-structured output beam so that the beam displays a uniform irradiance value. As this optical component homogenizes the radiance or irradiance value of the output beam and eliminates low frequency ripples from the beam, it is clear why it is named a homogenizer. A beam homogenizer is useful in plenty of laser applications. Otherwise, the laser processes will fail due to the irregularity of the beam.

Types of Homogenizers

Beam homogenizers can be of different types. Gaussian diffusers, such as opal glass diffusers or ground glass diffusers are the simplest and non-shaping homogenizers. Even though these homogenizers offer excellent homogenization, they do not transform the beam into a flat-top beam profile.

To achieve homogenization along with shaping the beam, one can use a micro-lens array which will subdivide an incident beam into several lenses and then combine them after reaching a certain distance. Nevertheless, the main issue with these arrays is that because of the lens pitch, order artifacts can arise inside the beam pattern.

Another way to homogenize and shape the input is to pass the beam through a lengthy multi-mode fiber. When the beam comes out of the fiber, it would be free from any radiance irregularity as the fiber’s net effect will combine the beam several times across the fiber. This approach involves connecting to a lengthy fiber, which can lead to losses in both propagation and connection, and be problematic in high power laser applications.

A much better and simpler way to homogenize a beam is by using a beam shaping diffusers, such as a diffractive diffuser or broadband diffuser. These homogenizers provide controlled flat top profiles with no order artifacts.

Homogenizer Working Principle

A beam homogenizer working principle basically involves combing or mixing several input beams with different characteristics to generate a uniform output beam. On a DOE window, most beam shaping homogenizer or diffuser elements are produced. As the diffuser introduces a specific diffusion angle, by selecting a focusing lens with an appropriate EFL, one can control the size of the image on the image plane. The setup for the homogenizer to work involves a laser beam, a homogenizer and sometimes a focusing lens.

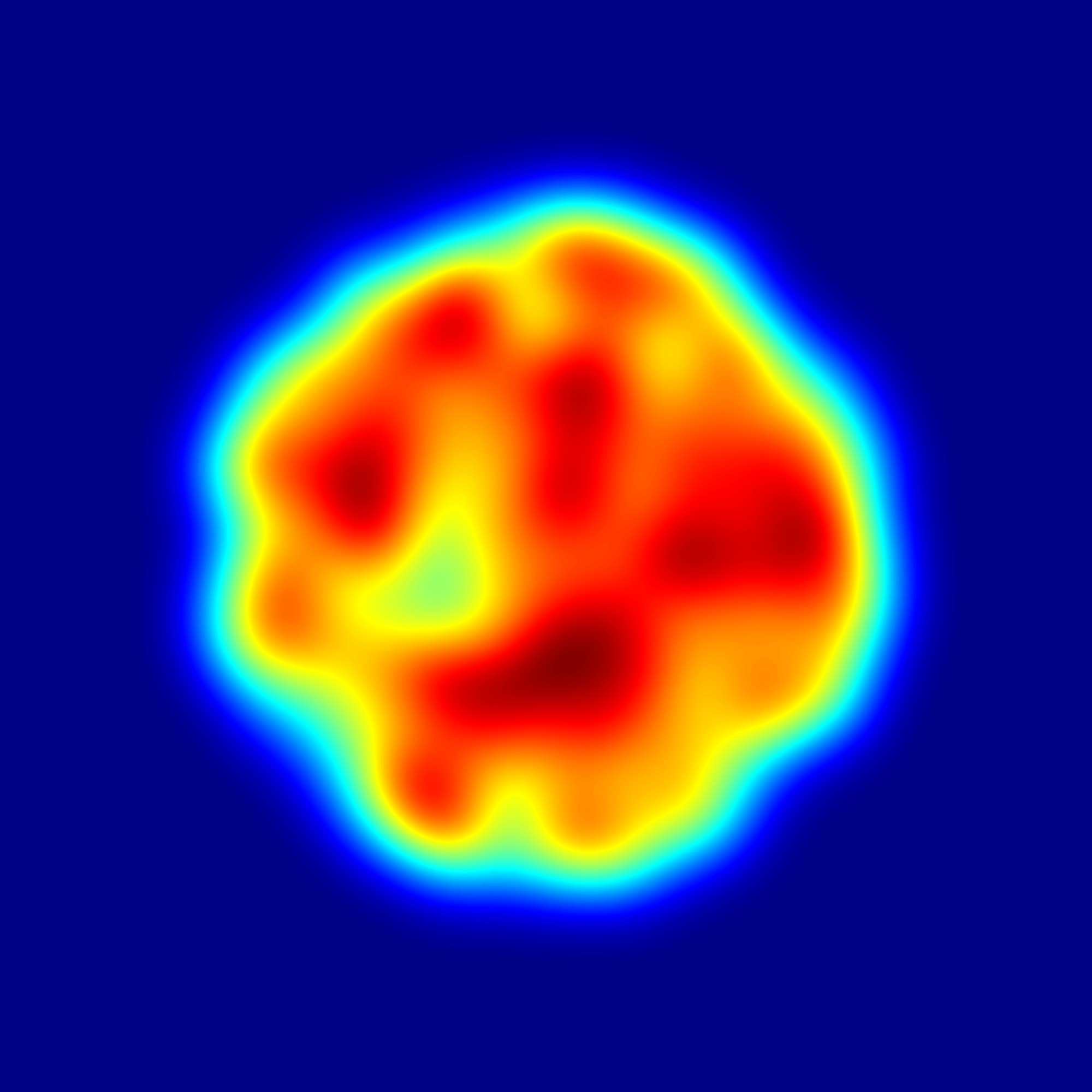

An effective way to homogenize an input beam is to use a diffractive diffuser. This method not only helps to homogenize the input beam effectively but also helps to achieve any desired shape for the output laser beam, such as circular, rectangular, or other geometrical shapes. The diffractive diffuser follows the operating principle of controlled combining of split beams. The diffractive diffusers split the input beam in a semi-random direction in order to attain the anticipated shape of the intensity profile in the local plane or far-field.

Applications

There are various applications of a beam homogenizer. Some common applications are found in laser projection systems, aesthetics, and medicine. A beam homogenizer is also useful for any material processing that involves lasers. In lithography processes, imaging systems, and lidar systems, homogenizers have crucial applications.