Today, through the use of various techniques, it is possible to obtain steel angles in a variety of sizes and dimensions. Thanks to the use of multiples techniques, some of which are unique, it is possible to produce both equal and unequal stainless-steel angles, in order to fulfil the demands of many areas.

Since these structural profiles are used in many areas, it seems reasonable that each company’s needs for finish, tolerances, and material will likewise vary.

How they are produced

Generally, technologies such as extrusion, rolling and cold drawing are used for the production of steel angle profiles. However, when the dimensions, material or even the type of profile become very specific, then the companies producing these kinds of structures prefer to use alternative methods.

For instance, when producing stainless steel unequal angles, in addition to the above technologies, laser welding is often used together with hot-rolling: in this way, stainless steel angles profiles with very different sides can be produced quickly and cost-effectively, thus meeting all kinds of demands.

However, in many cases, laser welding is also used for equal stainless-steel angles as the only technology; in practice, stainless steel bars are produced which are then welded to make the profile.

When using stainless steel angle profiles

There are many areas in which equal and unequal stainless-steel angles are required. Starting with the construction sector, where this kind of object is used both as a finish and in some load-bearing structures, to the industry, trade, in various types of machinery or in furniture production.

Since it is possible to produce angle profiles in stainless steel as well as in aluminum or other alloys, as such as carbon steel, it is quite clear that their range of applications is expanding exponentially.

However, stainless steel angles are the most widespread due to their intrinsic characteristics, which derive from both the structures themselves and the material they are made of.

The profile’s section, which can be T-, H-, C- or L-shaped, even with deeply unequal leg angles, makes it possible to achieve particular strength and stress resistance. Clearly, the most suitable kind of profile must be carefully evaluated for each area of use.

Characteristics of a steel profile

Steel profiles are so widely used for a number of reasons.

Firstly, for the easiness of production: as we have said, specialized companies are able to meet a wide range of demands that include profiles with unequal angles or with very particular profiles. All of this is done while maintaining a reasonable cost and providing the profile good strength, stress resistance and low weight.

In the construction sector, as well as in various other areas of use, stainless steel angle profiles are employed because they guarantee a long service life. Furthermore, these objects can maintain their physical and chemical properties, even when exposed to the weather or ongoing loads.

Obviously, the more attentively the right stainless-steel profiles have been chosen, the more realistic this last factor becomes.

Hot rolling: what it is

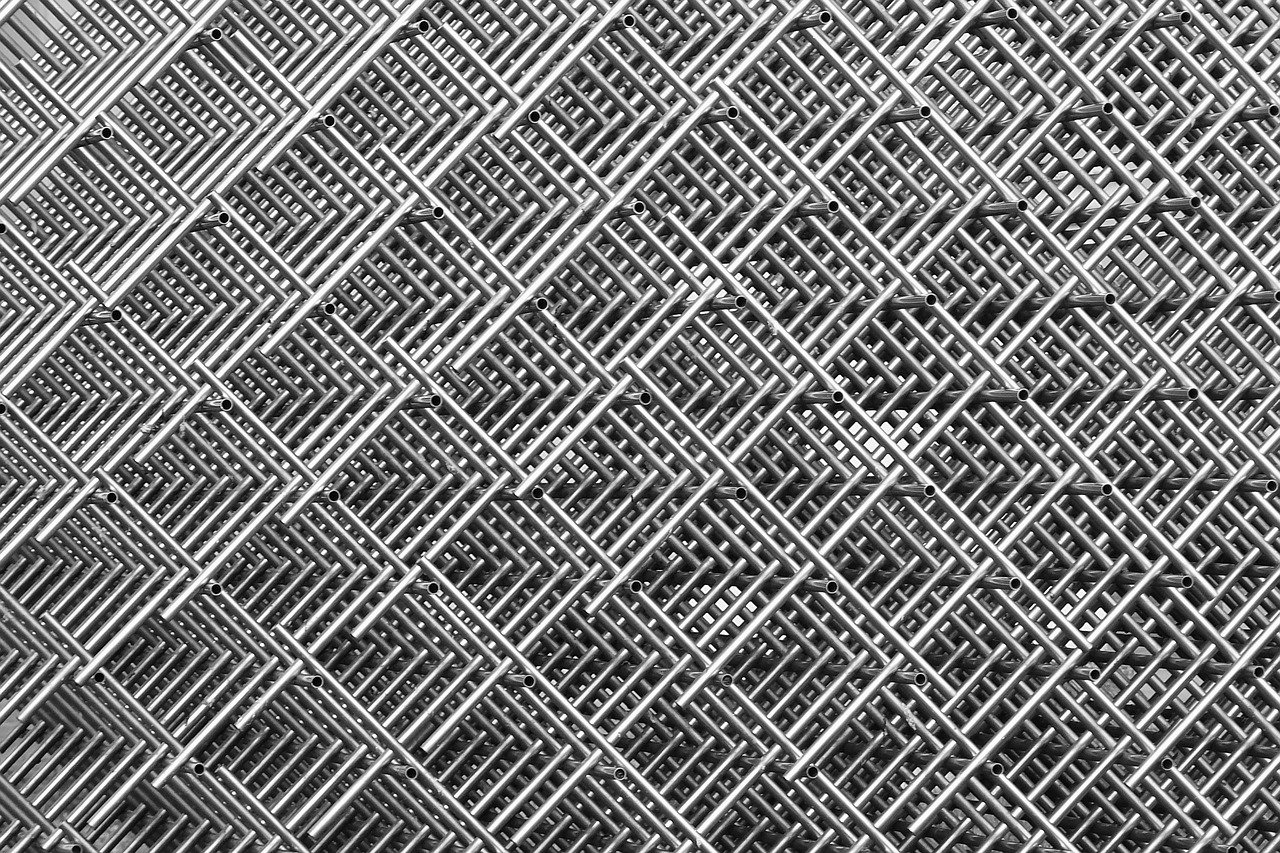

As we have already mentioned, stainless steel angular profiles with unequal sides are manufactured by hot rolling.

This technology uses a special rolling mill based on wire rods or billets, which have a maximum diameter of 60 mm; the wire rods are heated during the rolling process at a temperature of about 1100 °C. Then, components are “molded”, or rather continuously rolled passing through jigs, or ‘cages’, which gradually shape it to the desired shape and size.

Because of this manufacturing method, the resulting profile section is full and solid. This production setting, together with the low costs of tooling, allows even relatively small lots to be produced without making the process excessively expensive.

In general, hot-rolled profiles can be produced either in bars with a maximum length of 9,000 mm and a maximum diameter of 90 mm. The stainless-steel angle profiles, thus produced, are then laser-welded in order to obtain the finished angle profile.

Given that we are actually considering steel angle profiles with unequal sides, it is feasible to create structures whose two sides differ significantly from one another by combining two distinct manufacturing methods.

The use of two different but complementary techniques allow excellent tolerances to be achieved, while the total production cost of the stainless-steel angle profiles is maintained low. On the other hand, laser welding is mainly used for the production of sharp-edged, U-shaped, T-shaped or very large cross-section profiles.